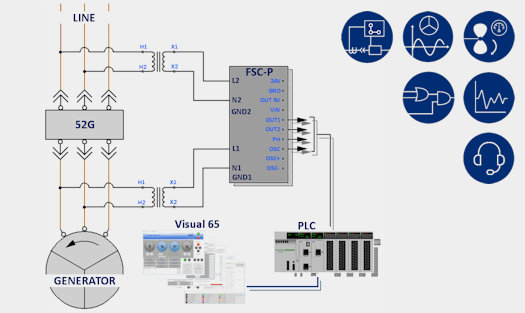

PLC-TG Hydro ECI Digital Speed Governor

A speed governor is at the core of the powerhouse operation. Its features, added to the mechanical quality of a turbine, are what brings to your generator and site its reliability, repeatability and smooth delicacy during operation.

Quality on a governor implies a large number of customizable parameters that may provide you the necessary tools to maneuver through the features that made the design of your site and components so specifically unique.

Hydro ECI’s governor design includes in its features and parameters not only the specifications common to all governors but also the demands and experience of a qualified stable crew of engineers and technologists that have been, performed and participated in designs, implementation and commissioning’s of turbines and sites that go by the hundreds plus tenths of years working as a team.

A proven and robust universal design that has been successfully used on all major types of new and rehabilitated turbines. From camelbacks, simple and double regulated Francis, horizontal and vertical Kaplans up to multi-injector/deflector Pelton turbines. Used by and with the major turbine makers on sites all over North-America, the Hydro-ECI PLC-TG governor is chosen either for new installations as well as replacement solution to existing governors on decades old turbine/generators.

- Fully IEEE STD125 compliant,

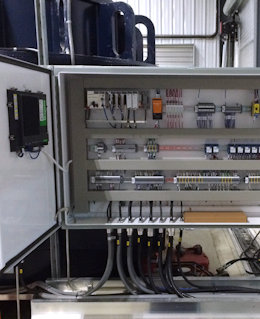

- PLC based digital design that allows for:

- Easy input/output remapping,

- Standard off-the-shelf / readily available replacement parts,

- Easy integration of custom components unique to existing installations,

- Optional controller and i/o redundancy,

- Universal design and software applicable to all turbines types, allowing asset managers to unify spares, maintenance, training and comprehensive configuration.

- Hot synch capability,

- Fast load rejection recovery,

- Auto-synchronization,

- Black start / islanding mode,

- Position, flow and power load management modes.

- Easy and flexible maintenance modes for faster component diagnosis,

- Fully parametrized and configurable options that cover: Positioning parameters, speed control, ramping, configurable speed switches, flow and power profiling, droop, etc.

- Windows based interface for configuration and monitoring that include real-time trending, high speed logging and multi-level granular user/password credential parameter configuration,

- Hard-wired and network operation options which allow for hybrid real-time and redundant remote parameter application,

- Default Modbus-TCP ready, status and parameter entry and exchange towards control units, plant HMI or remote SCADA.

Governor features